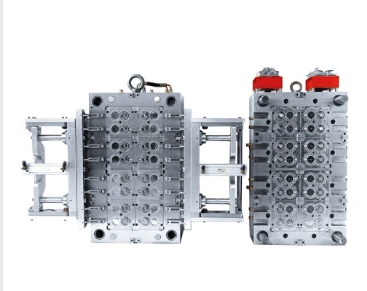

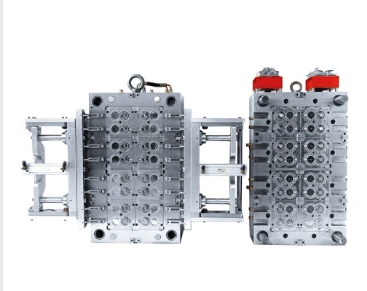

Blowing moulds are crucial for creating plastic products with hollow interiors, such as bottles and pipes. To ensure the success of the moulding process, it is essential to consider specific factors during the design and manufacturing of blowing moulds. In this article, we will explore the key considerations for creating high-quality Blowing Mould.

Material Selection: The first consideration is the type of material to use for the mould. Commonly used materials for blowing moulds include aluminum, steel, and copper alloys. The material should be durable, corrosion-resistant, and machinable, ensuring that it can withstand the pressure and heat of the moulding process. The material should also be compatible with the type of plastic material that will be used for moulding. Mould Design: The mould design is another critical consideration for successful blowing moulding. The design should be precise and accurate, ensuring that the mould halves fit together correctly. The design should also incorporate the necessary mechanisms for releasing the final product, such as ejector pins and sliding cores. Consideration should also be given to the number of cavities in the mould. Multiple cavities can increase production speed but may impact the weight and quality of the final product. Mould Manufacturing: The manufacturing process of blowing moulds is complex and requires attention to detail. Accuracy is essential in manufacturing, and machining should be precise to ensure the mould meets the exact specifications of the design. The manufacturing process should include heat treating, polishing, and assembling of the mould halves. It is also crucial to conduct rigorous testing of the mould before use in the production process. Maintenance: After the creation of the moulds, maintenance is key to ensuring its longevity and functionality. Regular cleaning is necessary to remove any buildup in the moulds that could impact their function. Inspections should also be conducted regularly to identify any damages, such as cracks or wear and tear, which could impact the final product. Conclusion: In conclusion, designing and manufacturing Blowing Mould is a crucial aspect of the plastic manufacturing process. Key considerations such as material selection, mould design, manufacturing, and maintenance are essential to creating high-quality moulds that guarantee successful moulding. With attention to detail, you can ensure that your blowing moulds meet exacting specifications and create high-quality plastic products.