Blowing Mould and Injection Mould are two types of moulds commonly used in the plastic manufacturing industry. Both of them serve the purpose of creating plastic products, but they differ in several aspects. In this article, we will help you understand the differences between them.

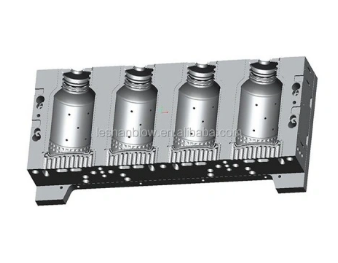

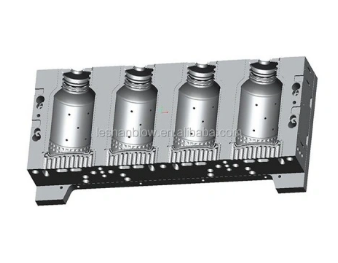

Blowing Mould: Blowing Mould is a type of mould used to create plastic products with hollow interiors. The mould consists of two halves that are designed to fit together tightly. The plastic material is melted and molded into the desired shape by compressed air or mechanical force. This process is called extrusion blow molding. The mould is designed to expand, creating a hollow space that forms the inside of the plastic product. The blowing mould is ideal for creating plastic bottles, pipes, and other similar products. Injection Mould: Injection Mould, on the other hand, is a type of mould used to create solid plastic products without hollow interiors. In this process, the plastic material is melted and injected into the mould. The mould consists of two halves that are designed to fit together tightly, similar to blowing mould. Once the melted plastic material is injected, it is left to cool and solidify, forming the final product. Injection moulding is ideal for producing toys, car parts, and other solid plastic products. Differences: The main difference between the two types of moulds is the final product. Blowing mould creates hollow plastic products, while injection mould makes solid products. Another difference is the application of force. Blowing moulds rely on compressed air or mechanical force to shape the plastic material, while injection moulds use pressure to inject the melted plastic into the mould. Conclusion: To sum up, Blowing Mould and injection mould are both useful in the plastic manufacturing industry. They serve the purpose of creating different types of plastic products, with varying sizes, shapes, and features. The main difference is in the final product and the application of force. If you are considering plastic production, consider which mould will be best for your desired product.